Free Service Hotline:

Free Service Hotline:

Welding is one of the most important process technologies in manufacturing. It has become more and more widely used in machinery manufacturing, nuclear industry, aerospace, energy and transportation, petrochemical, architecture and electronics industries. With the development of science and technology, welding has developed from a simple method of connecting components and blank manufacturing means to become a basic process in the manufacturing industry and the production of precise size of the finished product means of production. Traditional manual welding has been unable to meet the quality and quantity requirements of high-tech product manufacturing.

Electronic technology, computer technology, numerical control and the development of robotics for the welding process automation provides a very favorable technical basis, and has penetrated into the welding field. Welding automation production is an inevitable trend.

As a comprehensive advanced process technology closely related to the development of emerging disciplines, welding automation technology involves materials, machinery, electronics, information, control and other multidisciplinary cross-cutting areas. Its automated production process includes material preparation, cutting, assembly, welding, inspection and other processes, thus composing the automation of the whole process of welding product production. Only by realizing the mechanization and automation of this process, can we get stable welding product quality and balanced production rhythm, while obtaining high labor productivity.

Since the introduction of the world's first industrial robot in the United States in 1962, millions of industrial robots have been put into production applications around the world. Soldering robots, also known as automatic soldering machines, are used in soldering stations. Unlike wave soldering, reflow soldering and other over-oven soldering, it is mainly used for simple and repetitive manual soldering equipment.

Welding robot is a revolutionary advancement in welding automation, which breaks through the traditional way of welding rigid automation and opens up a flexible automated production method. Welding robots make it possible to automate the welding production of small-lot products. In a kind of welding robot production line, weldments can be welded automatically at the same time.

The main advantages of welding robots are as follows:

1. Stabilize and improve the welding quality and ensure its uniformity

2. Improve labor productivity, with 24 hours of continuous production a day

3. Improve the labor conditions of workers, which can work in harmful environments

4. Reduce the requirements for workers to operate the technology

5. Shorten the preparation cycle of product modification and replacement, and reduce the corresponding investment in equipment.

6. It can realize the welding automation of small batch products

7. It can complete the welding operation which is difficult for workers to carry out

8. Provide technical basis for welding flexible production line.

Soldering machine is a mechanical equipment, equipped with large-size transparent window to observe the whole soldering process, which is very important for product development and process curve optimization. Temperature control adopts high-precision intuitive intelligent controller, programmable perfect curve control. It controls temperature accurately, and the parameter setting is simple and easy to operate. It can complete CHIP, SOP, PLCC, QFP, BGA and other forms of all packages of single and double-sided PCB board welding. Its work efficiency is extremely high, a welding machine plus a screen printing table and two workers, a day can be completed the largest size of the PCB board nearly 100 pieces, the small size can be up to thousands of pieces. Soldering machine changed the soldering machine can only rely on natural cooling or pull out the PCB board in the soldering machine outside the cooling practice, so that the reflow soldering process curve is more perfect, to avoid the surface mount device damage and welding displacement problems.

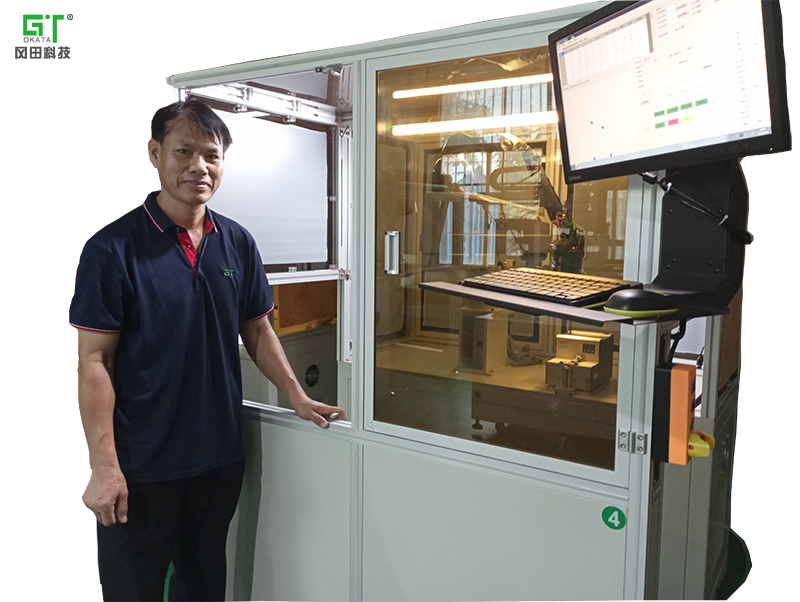

Okata specializes in the production of automated soldering machine manufacturers, with 16 years of design team, is an old brand to do the soldering machine started, unanimously through the many customers praise!